Stress or load: Force over area (has units of Newton per square metre)

Strain or deformation: Change in length over original length caused by applied stress or load (unitless and expressed as ratio or percentage)

Mnemonic: If your boss is under a lot of stress, his personality changes (strain)

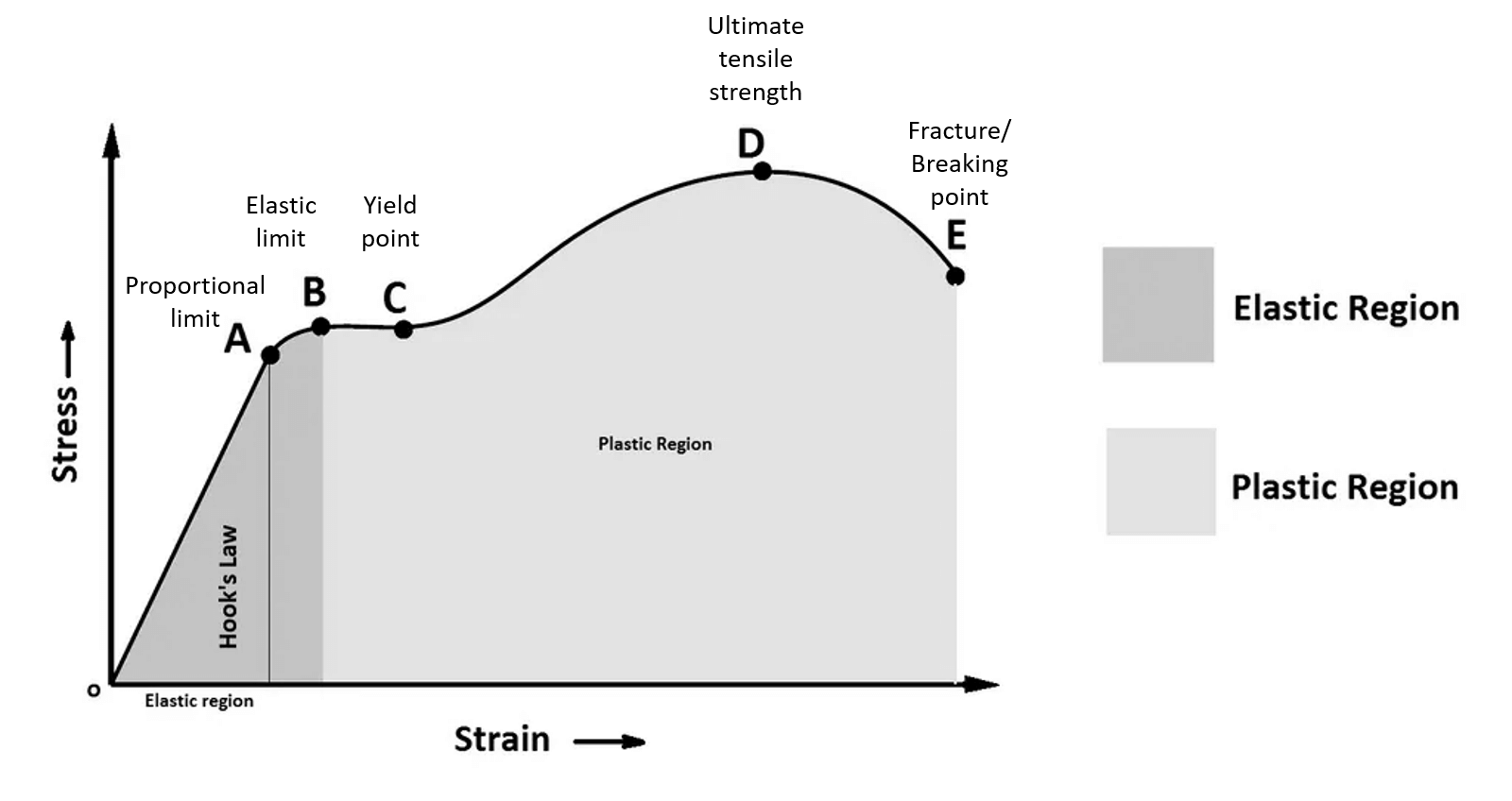

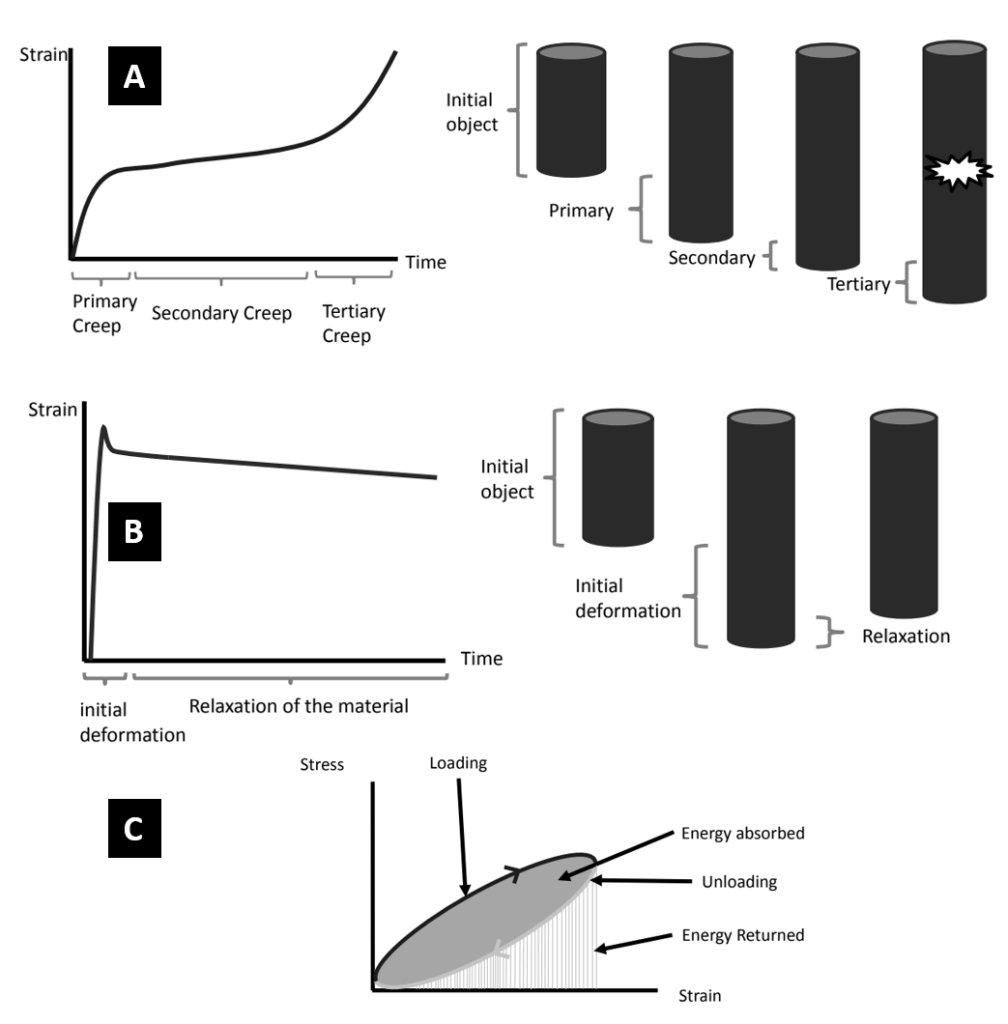

A. Elastic zone: The molecular bonds are stretched but not broken

- A = Proportional limit: Point upto which Hook’s law (Stress is directly proportional to strain) is obeyed

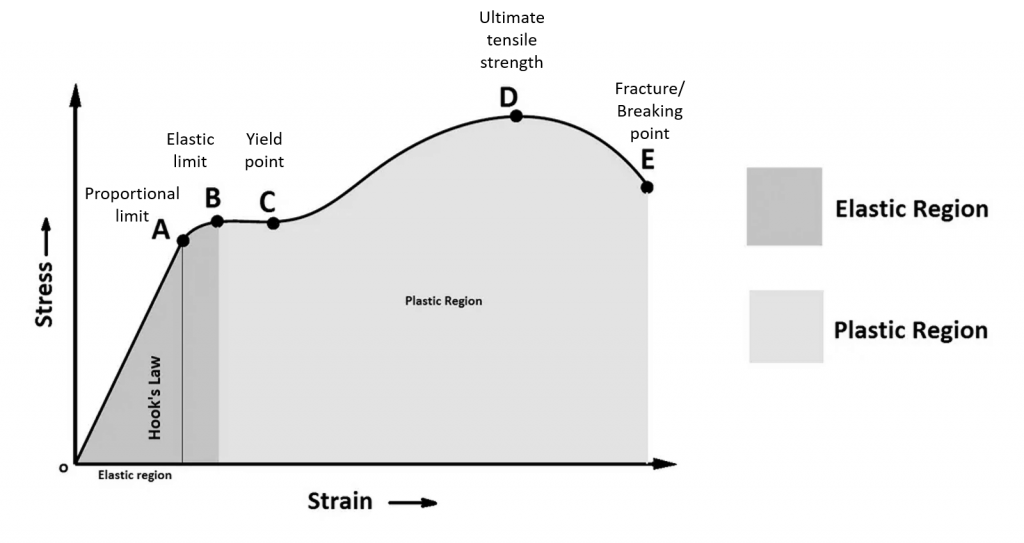

- Young’s modulus of elasticity = Stress/Strain (Higher modulus = Steeper curve = Stiffer material)

- B = Elastic limit: Point at which deformation stops being entirely reversible

B. B-C: Yield stress – stress needed to induce a specified amount of permanent strain, typically 0.2%

- C = Yield point: Point at which the material starts to undergo plastic deformation

C. Plastic zone:

- C-D = Ultimate stress: Maximum stress that the material has to bear before break or failure

- Yielding: Once, the yield point is passed, the material will undergo considerable elongation (yielding) with little or no increase in stress (flat part of curve)

- Strain hardening: the plastic deformation increases a material’s resistance to further deformation due to the material undergoing changes in its atomic and crystalline structure

- D = Ultimate stress point

- D-E = Necking: Zone where stretching occurs with an actual reduction in the stress due to reduction in cross-sectional area

Toughness (Strain energy): Area under the stress–strain curve represents the energy absorbed per unit volume of the material. It therefore indicates the energy absorbed by the material to failure. This is called toughness.

Stiffness: is defined as the slope of a force versus displacement graph.

Strength: is an imprecise term and represents the degree of resistance to deformation of a material. A material is strong if it has a high ultimate tensile strength.

Hardness: describes a material’s resistance to localized surface plastic deformation, e.g., scratch or dent.

Ductile: Large deformation between elastic point and breaking point (sees post-yield deformation)

Brittle: Small deformation between elastic point and breaking point (linear up to failure)

Fatigue failure: Failure of material by stress below ultimate tensile strength

Endurance limit: Stress below which unlimited cycles of load can be applied without failure

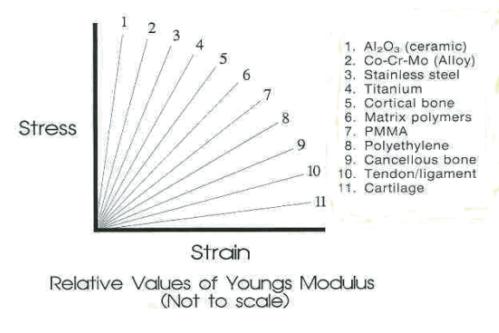

Viscoelastic behavior

In a viscoelastic material, stress-strain behavior is time-rate dependent, i.e., they react differently when loads are exerted over different time periods. It relates to a material’s ability to adjust to that load given time. Characteristics of a viscoelastic material include –

1. Creep

- Applied stress or load is kept constant

- Progressive deformation of material is observed (deformation is permanent) over time

2. Stress relaxation

- Strain is kept constant

- Stress peaks and relaxes over time

3. Hysteresis

- The energy lost from the deformation since viscoelastic materials are not perfect elastic materials